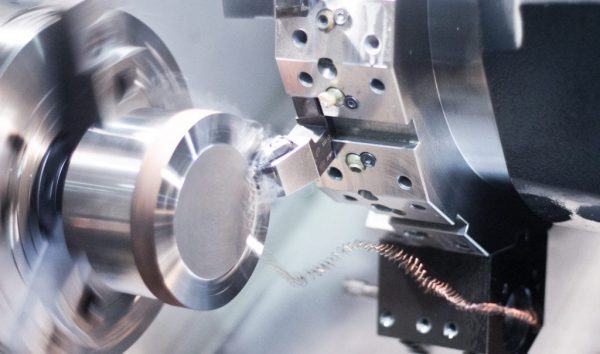

CNC (Computer Numerical Control) machine makes the manufacturing process efficient and helps create a standard approach to production across the whole operating system. A CNC machine lasts longer, requires less manpower, and offers better accuracy compared to manual machining.

A CNC machine comes in various dimensions, speeds, sizes, and shapes. So if you are looking to choose the best CNC machine for your business, the following are tips to look at:

1. Consider the Intended Applications

There are many CNC machine categories, all of which have their own ideal use cases, pitfalls, and perks. Your only task is to determine which can mesh with your business applications.

For instance, if your aim is cutting intricate designs into woods and metals, a CNC laser machine can fit the bill. It is also suitable if you want to work with sheet metal, bend and shape them in order to create bigger-scale parts.

At the same time, dealing with wood or steel to fashion uniforms, symmetrical parts will be suited to a mill or CNC lathe.

In other words, if you know what to achieve with the piece of equipment, you can narrow down your options while focusing on those that are more relevant.

2. Look at the Specification and Software

The length or range of CNC axes as well as the spindle motor power is regarded as the major specifications of CNC machines. The same machine may have dissimilar configurations in terms of motor power.

On the other hand, not friendly or difficult software will increase the time of product design or time of setup. This is why it is wise to opt for software programs like Easel Software to automate processes and ensure products are manufactured consistently and repeatedly.

3. Value and Performance

When using a CNC machine for your business, it is imperative to know what it is capable of. So when choosing the machine for your business, you might want to determine whether you will be using it for engraving, pocketing, or cutting.

There is a market for such a machine, which may cater to various requirements. Especially, desktop CNC machines can provide you with good results from the tabletop workspace.

Always consider choosing a CNC machine with high-quality control. If the materials are too thick or weak for production, they can’t perform in sync with the process of manufacturing.

By taking these aspects into account, you will be free of heavy time consumption, poor results, and damaged equipment and be able to go for the right CNC machine.

4. Check the Machine’s Speed

The speed of the machine is also called the feed rate. So when looking to buy a CNC machine for your business, consider checking the machine’s feed rate. This helps to dictate the rate at which you may cut materials during the process of manufacturing.

Final Thoughts!

Investing in the best CNC machine for your business will yield a lot of benefits. CNC machines tools, such as 5-axis machines, are suitable, especially if you combine state-of-the-art technology with the flexibility in different machining components. So whether you own a small or big business, ensure you consider the machine’s speed, value, performance, software, and intended applications.

5 Ways Wasp Infestation Can Be Dangerous in Branson, MO

5 Ways Wasp Infestation Can Be Dangerous in Branson, MO  Top Considerations When Choosing a Magento Hosting Provider

Top Considerations When Choosing a Magento Hosting Provider  Are we able to possess a specific quantity of domain names?

Are we able to possess a specific quantity of domain names?  essential ways to secure network switching

essential ways to secure network switching  classification of garments

classification of garments  What Is The Difference Between Web Hosting and CDN?

What Is The Difference Between Web Hosting and CDN?